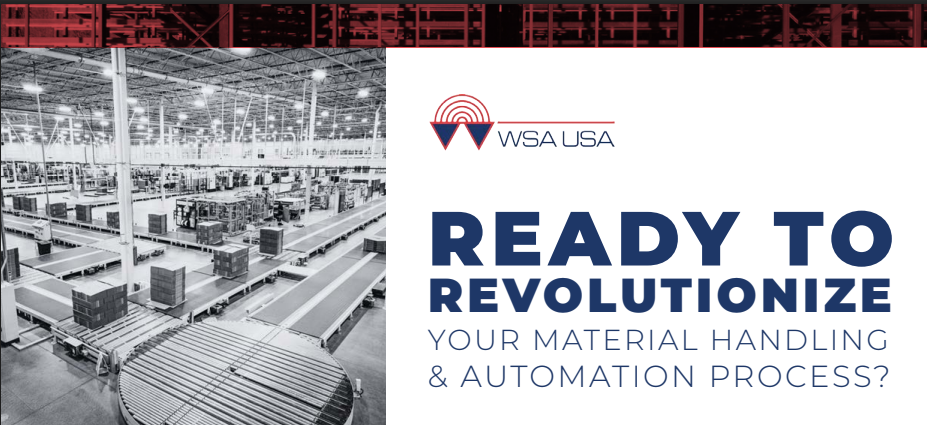

Customized automation solutionsfor your entire plant

Whether you’re outfitting or upgrading a plant or just looking for specific machinery, WSA-USA is a reliable partner with innovative products and world-class solutions for the corrugated industry.

Planning

We have a design process that ensures projects are being considered not just for the now, but the future as well.

Innovation

We integrate the entire material handling system with your plant’s scheduling and manufacturing system for a fully automated solution.

Simulation

We create the most efficient and productive material handling solutions to deploy in the most advanced 4.0 Industry smart factories in the world.

Our Products

We’re corrugated industry leaders in providing full solutions to our partners, partly due to our comprehensive range of material handling solution products.

Conveyor Systems

WSA designs and manufactures a wide array of modular plastic belt and roller conveyor systems for some of the most automated corrugated smart factories in the world. Full Plant Systems are controlled by the WSA IFAS Intelligent Factory Automation System.

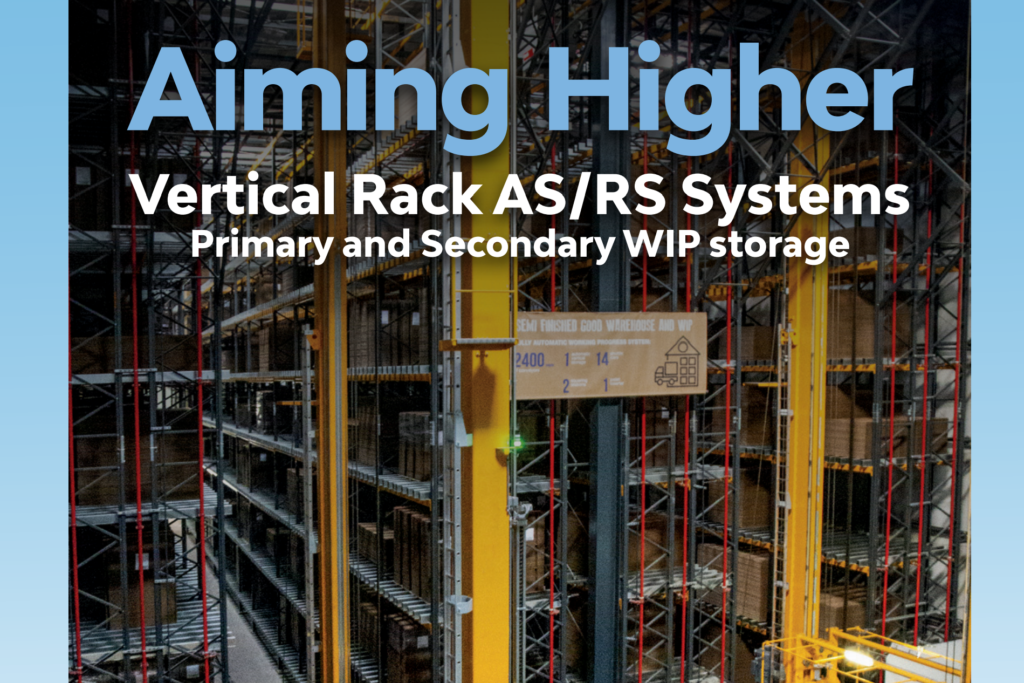

Vertical Rack AS/RS Systems

The WSA-USA AS/AR Vertical Storage System is a fully automated corrugated WIP handling system designed to maximize storage capacity and plant efficiency while reducing the overall footprint.

Plant Automation

At WSA USA, we are committed to our customers’ success. Our unique design and planning processes allow you to maximize productivity and efficiency while maintaining a safe working environment.

About Us

Our Cincinnati, Ohio location was founded in January of 2011. Thanks to our partnerships with our customers we’ve been able to be the first to bring multiple solutions to the market with over 40 patents on new designs of equipment. We are a full-solution company, allowing each of our customers to gain overall savings and efficiencies in their plants.

WSA Signature Process

Collaborating with WSA means forging a partnership where we deeply immerse ourselves in understanding your business and its unique intricacies. This insight allows us to develop tailored solutions that ensure your success. Leveraging WSA’s technological advancements, we can model and simulate plans, ensuring robust solution development and alignment. Our commitment continues through implementation and into a long-term service and support relationship ensuring the optimal, long performance of your investment.

Step 1: Information Gathering

Detail current plant infrastructure and layout; understand your future growth plans, throughput goals and team infrastructure to support your operation. Documentation of current state and future growth and throughput objectives feed directly into our plans of capacity and tools for modeling and simulation.

Step 2: Plan Development

Work directly with WSA leadership and dedicated project team, we utilize our proprietary “WSA 3D Twin Factory Simulator Model” to develop the layout and plans for your plant specifically. We will review the data-driven solutions to optimize machinery, software, and infrastructure to meet your goals.

Step 3: Implementation

The project kicks off with the dedicated WSA team and leadership, providing an overview of operative points of contact, finalized plant documentation, and a GANTT schedule for timing throughout. We prioritize transparency and regular communication to track progress, manage timelines, and maintain clear expectations. Rest assured, following successful implementation, WSA will continue to provide support for servicing and parts needs, ensuring a close partnership for your organization’s success for years to come.

You’re in Good Company.

“WSA USA is extremely creative. They provided solutions that were more cutting edge, using better technology. And they didn’t just look at the technology here in the U.S, they looked at the technology in Asia and Europe as well.” – Bob Cohen, President | ACME Corrugated Box