Robotic Palletizers and High Speed Load Formers

How We Help

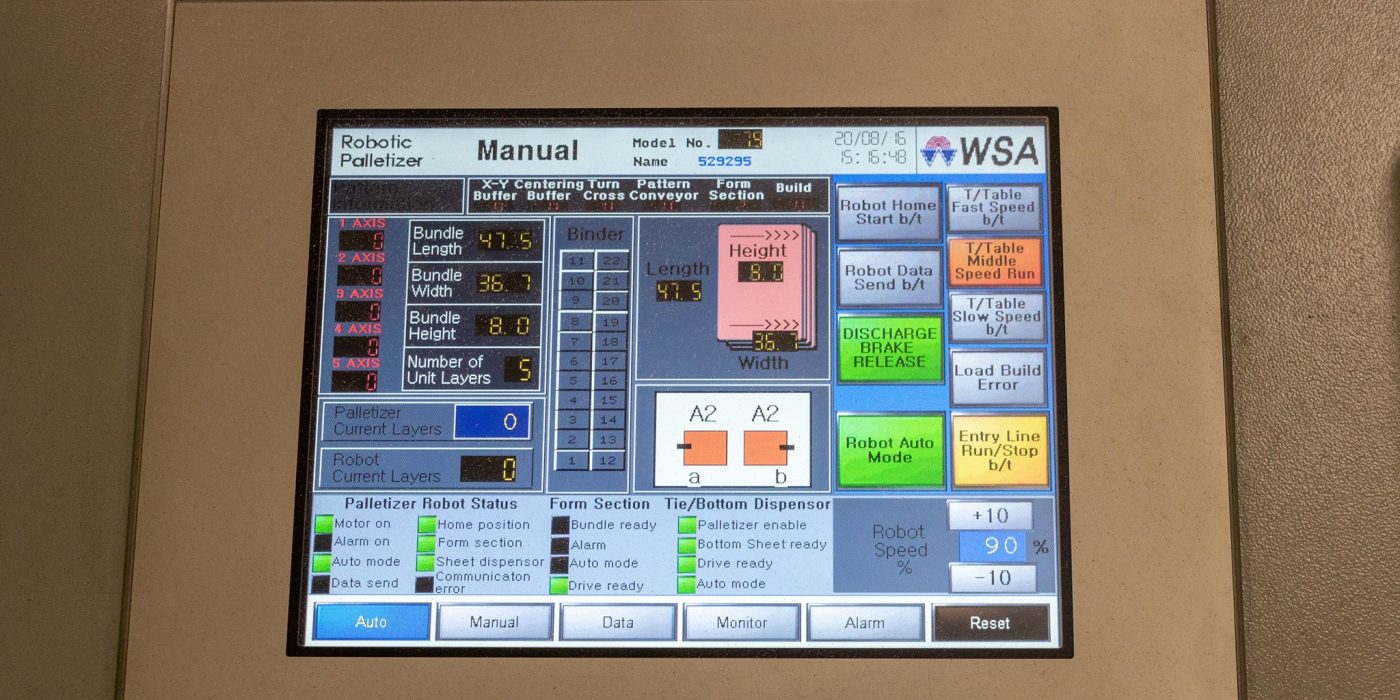

The WSA Robotic Palletizer is designed around the latest generation Kawasaki Robots. We start by forming the layers with our specially designed side shifting roller table which positions a single or doubled bundle into its correct orientation. The layer transfer robot is then used to transfer a single or double layer onto a bottom sheet or pallet in one movement. This operation allows for building loads at up to 30 bundles per minute. Utilizing these two processes provides for greater flexibility in stacking patterns and faster cycle times. Additionally, the layer transfer robot utilizes a unique basket design which provides for optimum handling in the transfer of layers. With all six sides of the layer being supported by the basket, we can achieve perfectly square finished loads. Some of the standard features of our robotic palletizer include:

- Centering Device

- Bundle Doubling

- Pattern Robot or side shifting roller table to form the pattern

- Tier Squaring Section

- Layer Transfer Robot

- Tie sheet & Bottom Sheet Inserter

- Pallet Master to unstack & deliver pallets one by one

- Internal Conveyors, Fencing, and Touch Screen Operator Interface

- Data Interface with press for fully automatic setup

The WSA Standard Load Former is by far the most well equipped unit in the industry with standard features including Plastic Belt Lift Conveyor for maximum load stability, Color Touch Screen Operator Interface with full bundle line controls, roller ball transfer table, 7-speed load discharge settings, variable load compression, Allen Bradley PLC, and much more. The WSA Standard Load Former is available in sizes of 1500 x 1800mm, 1800 x 1800mm, and 1800 x 2100mm. Options include a stainless steel air transfer table, pallet master infeed delivery system, and ethernet remote access interface. The WSA Tri-Zone Load Former was designed specifically for the latest high speed flexo folder gluers and is installed on the likes of MHI Evol and ISOWA Falcon machines which run at speeds of up to 400 boxes per minute. The unique design minimizes all cycle times over a conventional load former and allows for the fastest load discharge times in the industry. Maximum sustained running speeds can be achieved even when running a one up or one by two bundle stacking pattern.

The Tri-Zone Load Former features all plastic belt transfer conveyor for maximum load stability, a user friendly touch screen operator interface with full bundle line controls, an air transfer table . This model can also be equipped with an optional pallet un-stacking and infeed delivery system. Contact WSA to learn how to maximize the productivity of your new Flexo Folder Gluer with our High Speed Load Former solution.