Simulation

WSA USA is committed to being a leader in innovation. We create the most efficient and productive material handling solutions for our customers to deploy in the most advanced 4.0 Industry smart factories in the world.

How We Help

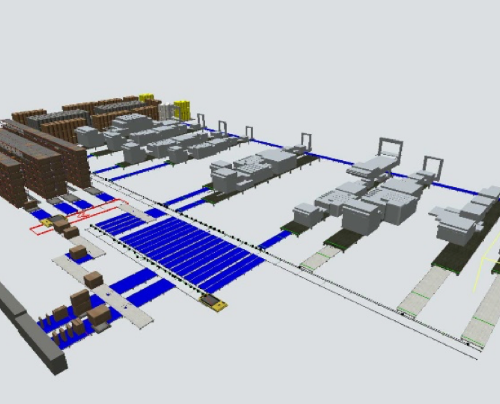

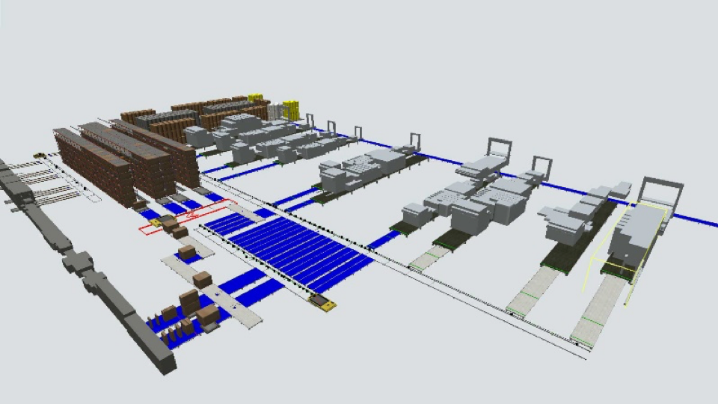

To help you evaluate and test the proposed solution, we create a customized simulation (2D and 3D modules) based on your real-time production data.

The only way to ensure our solution fits your needs is to demonstrate how it will work in your environment. We configure the variables to any specifics so you can understand how the solution will transform your plant or factory.

Real-Time Data

At a minimum, we collect data from your production schedule showing when a product was run off their corrugator with all the production order details, the time and duration it was stored and run on the converting machine, how it was palletized, and how it was processed on the finished good line.

The simulation enables us to identify potential bottlenecks and adjust the design to avoid systemic problems during implementation. This approach eliminates any preliminary design restrictions and helps ensure a successful system deployment.

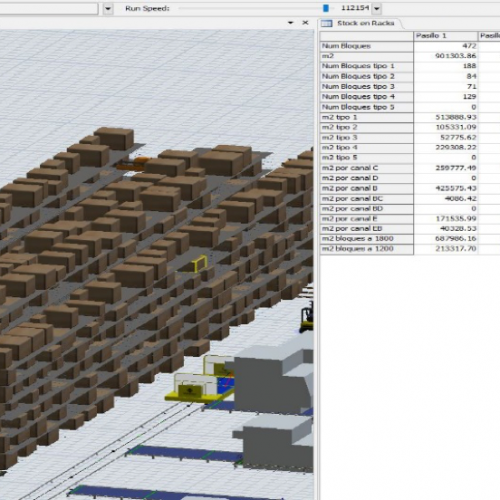

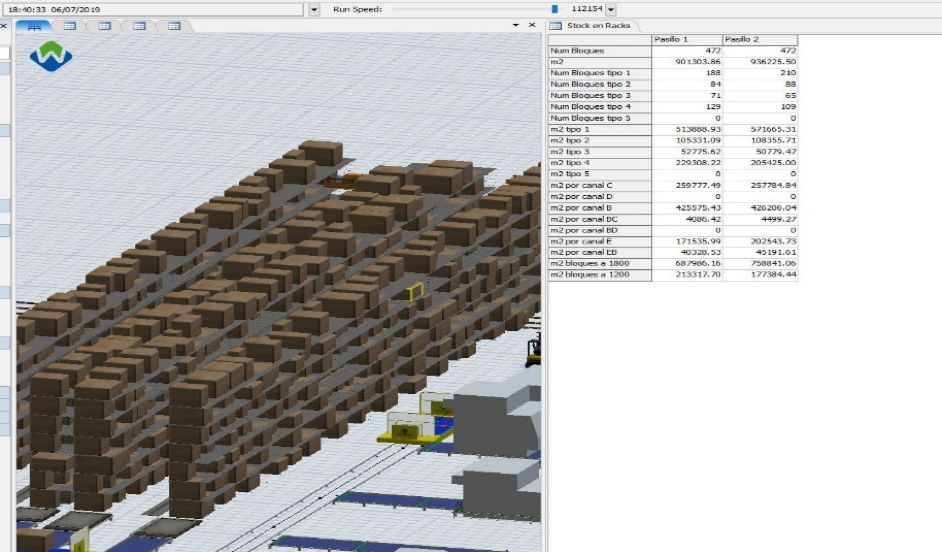

3-D Configurator Module

The simulation system’s 3D configurator module allows us to see real-time implications of the following variables allowing us to see real-time implications of such changing variables to the manufacturing process:

From this data, we can see the balance of the factory from corrugator to the converting machines to finished goods and identify any potential systematic issues.

We can also test the system to see what happens when one component (i.e., changing one of the components like a wider and faster corrugator, or a faster or additional converting line, or a change to the palletizing requirement or finished goods line, etc.) is changed.

Simulation gives us a virtual window into how the solution will operate under certain variables and enables us to tailor our innovative solutions for each customer. Please visit our Custom Simulations page for additional details on our offerings.

2-D Configurator Module

The simulation system’s 2D configurator module allows us to test in real time the actual PLC code that will be running on the conveyor system to be installed:

- Real time feedback from the sensors on the conveyor line

- Speed changes on the conveyor motors and resulting impact

- Post implementation bug fixes without affecting live production

- Using real time data from the customers ERP system to make future changes but testing with a simulated environment.

From testing all of the PLC logic prior to arriving onsite for commissioning allows our engineers to fix any issues prior to commissioning the system and also to speed the commissioning phase of installation up.

We can also test the system to see what happens when one component (i.e., changing one of the components like a second strapper line through shipping or running a mix of all long units instead of short, etc.) is changed.

Simulation gives us a virtual window into how the solution will operate with the exact layout for each customer being used for simulating.